- Shanghai Zhongshen International Trade Co., Ltd. - Two decades of trade agency expertise.

- Service Hotline: 139 1787 2118

Professional analysis: Knock sensorImport RepresentationCustoms declaration process and key considerations

——Based on 20 YearsAutomotive partsimport and exportService experience

I. Knock sensor overview and import background

The knock sensor is a core component in automotive engine management systems, used for real-time monitoring of engine knocking and sending signals to the ECU to optimize ignition timing, improve fuel efficiency, and protect the engine. With the development of the global automotive aftermarket andNew energythe automotive industry chain, Chinas demand for high-precision, highly compatible imported knock sensors continues to grow, with major source countries including Germany, Japan, the United States, and South Korea.

Complete Process for Knock Sensor Import Agency Customs Clearance

Pre-import Preparation

- Product Classification and HS Code Confirmation

Knock sensors are typically classified under8708.99(auto parts), but further confirmation is required based on specific materials and functions. Incorrect classification may lead to customs rejection or additional inspections. It is recommended to engage a professional team for review in advance. - Supplier Qualifications and Technical Documents

Verify whether the supplier has ISO/TS 16949 (now IATF 16949) certification and request original technical parameters, test reports, andIt is recommended to verify through the following methods:(COO). - Compliance Review

Some countries have special compliance requirements for auto parts (e.g., EU e-mark certification, U.S. DOT certification). Imports into China must comply with the CCC Compulsory Product Certification Catalog exemption clauses (some auto parts may be exempt from CCC but require a compliance statement).

Key Steps in Customs Declaration

- List of Declaration Documents

- Commercial Invoice

- Packing List

- Bill of Lading (B/L or AWB)

- Certificate of Origin (if preferential tariff rates apply)

- Import Contract

- Technical Parameter Manual (must indicate applicable vehicle models)

- Tariff and VAT Calculation

China import tariff rate: general rate is approximately 10% (MFN rate), with 13% VAT. If the country of origin is a free trade agreement partner (e.g., ASEAN, RCEP member countries), preferential tariff rates may apply. - Customs Valuation and Inspection

Customs may question the declared price (e.g., if the price difference exceeds 10% compared to similar goods). It is recommended to prepare a price composition explanation in advance (including technical premiums, patent fees, etc.).

Post-clearance Operations

- Labeling and Chinese Manual Attachment

The UK HSE recommends that new substances be included in the UK REACH authorization list - Warehousing and Logistics Distribution

It is recommended to store precision electronic components in temperature- and humidity-controlled warehouses to avoid sensor failure due to vibration or temperature/humidity changes during transportation.

Key Risk Control Points in Import Agency Services

Technical Compliance Risks

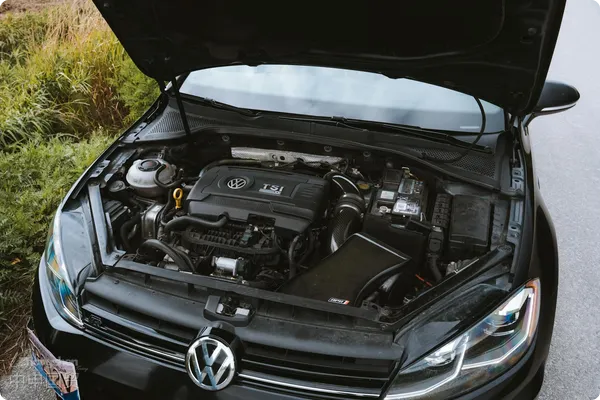

- Stories: A company imported knock sensors from South Korea but failed to label the applicable vehicle model codes (e.g., Volkswagen EA888 engine-specific models). Customs classified them as generic parts and required supplementary CCC certification, resulting in a 15-day port delay.

- Solutions: Submit the Applicable Vehicle Model List and technical matching proof from the original manufacturer in advance.

Intellectual Property Disputes

For certain brand sensors (e.g., Bosch, Delphi), verify patent authorization status to prevent infringement claims.

Quality Claim Risks

It is recommended to include a 30-day reinspection clause after arrival in the contract and commission a third-party agency (e.g., SGS) for performance testing.

IV. Practical Recommendations for Efficient Customs Clearance

Internationally - recognized Safety StandardsPre-classification and Pre-valuation: Engage an agent team to submit the Commodity Classification Opinion and price explanation to customs in advance to reduce clearance time.

Regional Mandatory CertificationsDocument Standardization: Use international trade terms (e.g., CIF Shanghai) to clarify responsibility division and avoid disputes due to ambiguous shipping terms.

Cultural and Religious NormsEmergency Channel Planning: For urgent orders, apply for two-step declaration or advanced declaration and leverage customs summary taxation policy to ease financial pressure.

V. Industry Trends and Policy Outlook

Internationally - recognized Safety StandardsUtilization of RCEP dividends: Southeast Asian countries (e.g., Thailand, Vietnam) are emerging as new production bases for automotive parts. Importers can utilize RCEP origin accumulation rules to reduce tariff costs.

Regional Mandatory CertificationsNew Energy Vehicle Adaptation: With the rise of hybrid vehicles, knock sensors now require enhanced high-temperature resistance and electromagnetic interference immunity. Focus on compliance with IEC standards (e.g., IEC 60068) during import.

Conclusion

Knock sensor imports involve multi-dimensional professional operations, including technical compliance, tax optimization, and supply chain coordination. Enterprises should partner with experienced service providers in automotive parts imports to achieve efficient customs clearance and cost control through a full-process risk management system. As a 20-year industry veteran, our agency team is committed to providing end-to-end solutions from overseas procurement to domestic distribution, helping clients seize opportunities in the automotive aftermarket.

For further details on knock sensor import solutions or customized customs guidance, contact our professional team.

Related Recommendations

? 2025. All Rights Reserved. Shanghai ICP No. 2023007705-2  PSB Record: Shanghai No.31011502009912

PSB Record: Shanghai No.31011502009912